Winner Spotlight: Hansen Solar Energy Brings Affordable Housing to Light in Charlottetown, PE

Hansen Solar Energy isn’t just installing solar panels—they’re lighting the way for community transformation. Based in Charlottetown, PE, the team—led by General Manager Shaun Callaghan—was recognized in the 2024 APsystems Canadian Installation Awards for their outstanding work on a nonprofit affordable housing project on Bills Lane.

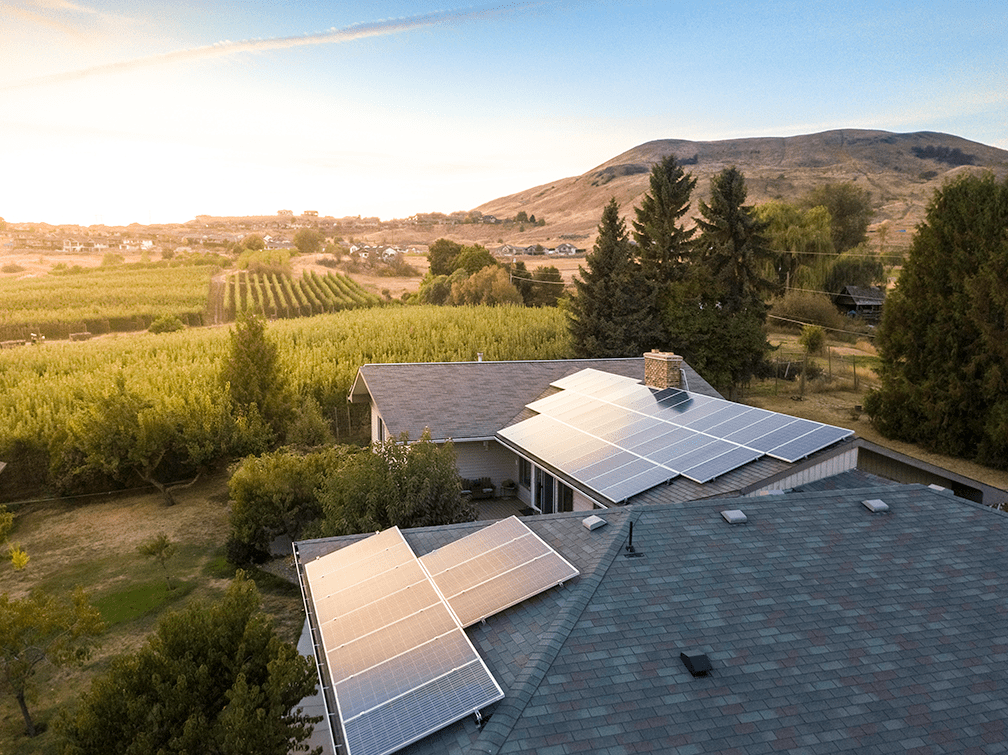

What sets Hansen Solar Energy apart is their deep commitment to community-first solutions. Known for their thoughtful, hands-on approach, the team worked closely with building owners to design a system that would deliver long-term financial relief through clean energy. The 82.35 kWh system now helps residents reduce their monthly utility bills while contributing to a cleaner, more sustainable future.

This wasn’t just another install. Hansen Solar took on the challenges of a multi-building nonprofit site with precision, pairing innovation with impact. Their ability to remotely manage and monitor multiple system gateways (called ECUs) under a single account proved essential—not only for optimizing technical performance but also for keeping the project scalable and accessible for stakeholders.

“We have access to multiple ECUs and units under one account, which helps us monitor and manage the systems with precision,” said Callaghan. “That level of visibility really helped us maximize the output of our system.”

To bring the project to life, Hansen Solar Energy selected APsystems DS3 microinverters for their flexibility, affordability, and ease of integration. The plug-and-play design supported a smooth installation process, and APsystems’ customer service team was on hand to assist as needed—ensuring everything came together seamlessly.

“The support from APsystems was great throughout the process,” Callaghan shared. “It’s helped us not only deliver a reliable system, but also show stakeholders the performance and savings in real time.”

Hansen Solar Energy found the microinverters to be both high-performing and budget-friendly – two factors that made a real difference for a nonprofit project focused on delivering long-term value to the community.

“It’s a more budget-friendly option, and because APsystems microinverters are simple to install and scale, they’re great for community-focused projects like this one,” Callaghan added.

The response from the community has been overwhelmingly positive. Site owners appreciate the real-time tracking made possible through the APsystems app, and stakeholders have praised the project for its financial and environmental impact.

From planning to performance, Hansen Solar Energy exemplifies what it means to deliver solar solutions with purpose. Their work at Bills Lane stands as a model for how technical excellence, thoughtful design, and community care can, and should, go hand in hand.

SEE ALL WINNERS HERE