The Future of Solar & Storage: How APsystems Is Using AI to Build a Smarter Energy Ecosystem

In today’s rapidly evolving energy landscape, artificial intelligence is transforming the way we generate, store, and manage power. From intelligent manufacturing to real-time optimization, AI is enabling breakthroughs across industries—and APsystems is at the forefront of this shift. By combining advanced solar and energy storage technologies with AI innovation, the company is reshaping what’s possible in residential, commercial, and DIY energy solutions.

Smart Integration of Solar, Storage, and AI

APsystems has long championed the convergence of solar and storage—now supercharged by AI. In the micro energy segment, the company’s EZ1 and EZHI series offer easy-to-install, plug-and-play systems that empower users to achieve energy independence on their own terms.

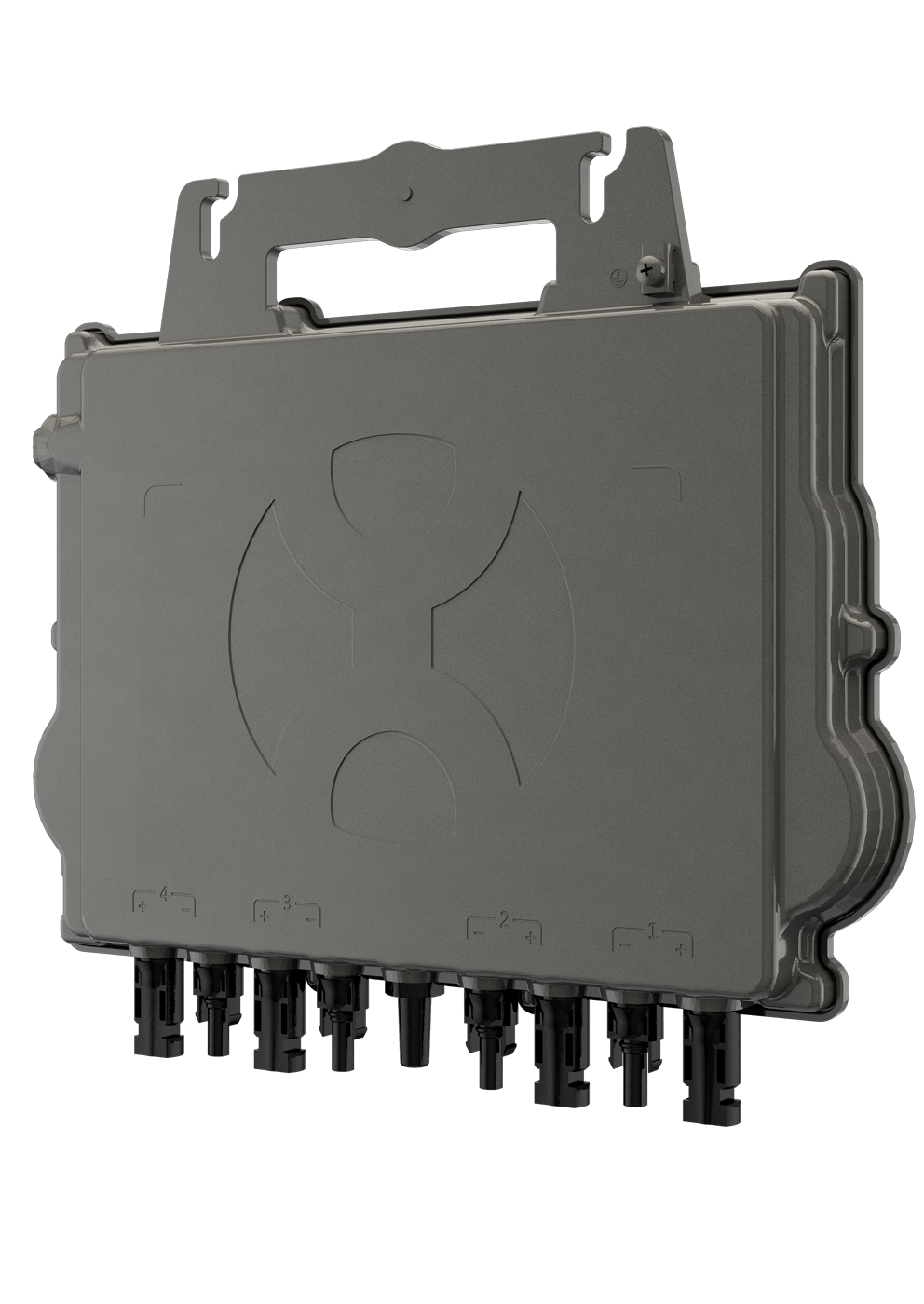

For residential applications, high-current 20A microinverters seamlessly pair with the APstorage ELS/ELT battery series to meet the dynamic energy needs of today’s households. In the C&I space, the three-phase QT2 microinverter delivers efficient, flexible performance for businesses aiming to lower costs and maximize output.

At every stage of the energy journey—pre-sales, installation, and ongoing operations—APsystems is embedding AI into its ecosystem. From intelligent design tools to smart energy management and AI-driven customer support, the goal is simple: increase system performance, reduce complexity, and elevate the user experience.

AI in Action: Optimizing Energy Management

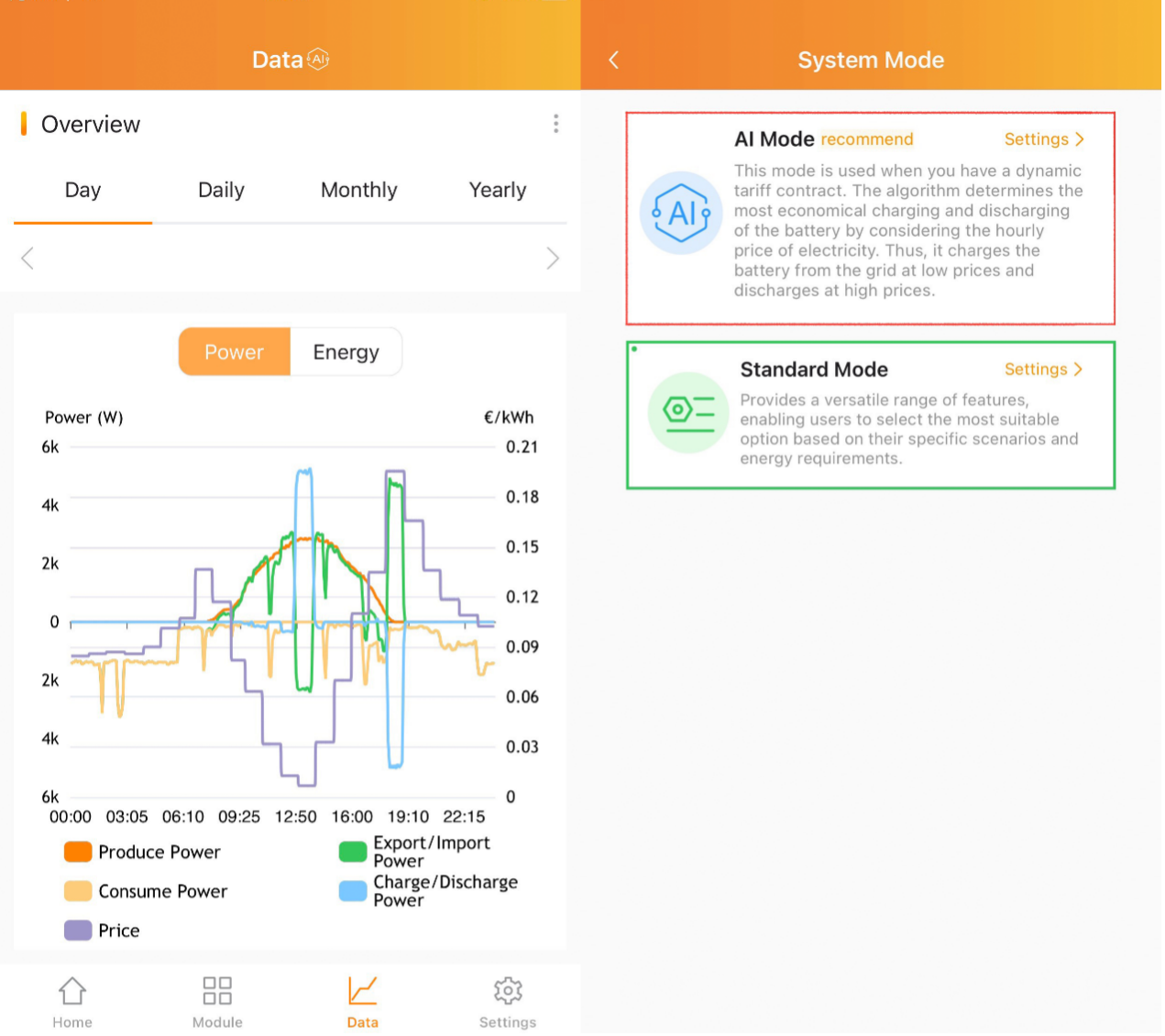

One of the most compelling examples of AI at work is APsystems’ “BESS AI” model. This advanced algorithm uses deep learning to analyze solar production, energy usage, and regional electricity pricing. It then generates a custom battery charging strategy for each home, which is automatically sent to the user’s energy storage system.

The result? Smarter use of stored power, reduced reliance on the grid, and greater savings—especially in regions with time-of-use pricing. For residential users, it’s a game-changer.

Designing Smarter with AP Designer

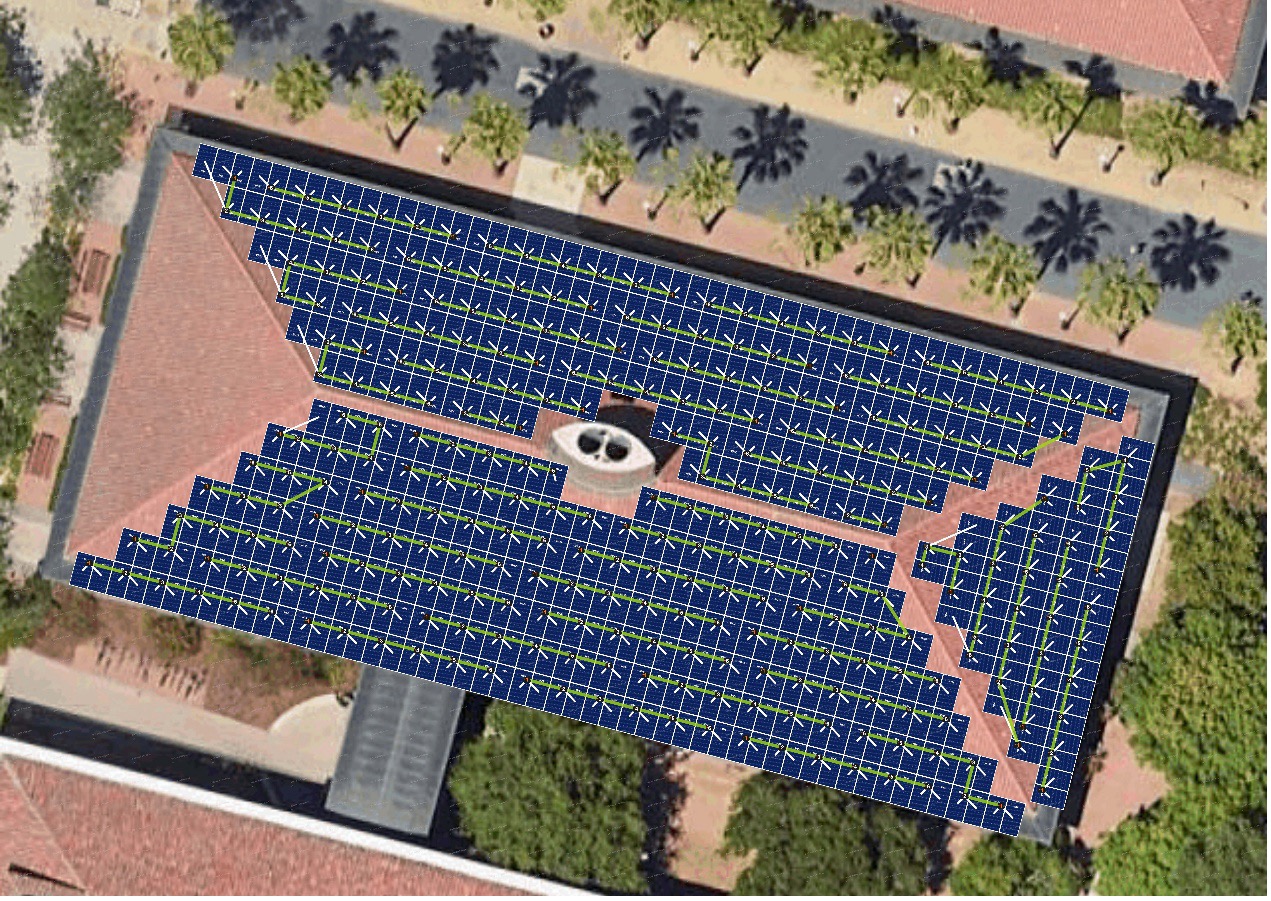

To simplify system planning, APsystems developed AP Designer, a powerful AI-driven solar design tool. By integrating satellite imagery, image recognition, and 3D modeling, the platform can assess rooftops, tree coverage, and shading to deliver one-click solar layouts with speed and precision.

The tool also produces professional-grade system diagrams, BOMs, cost-benefit analyses, and simulation reports—helping solar professionals cut design time while increasing accuracy.

AI-Powered Customer Support with APbot

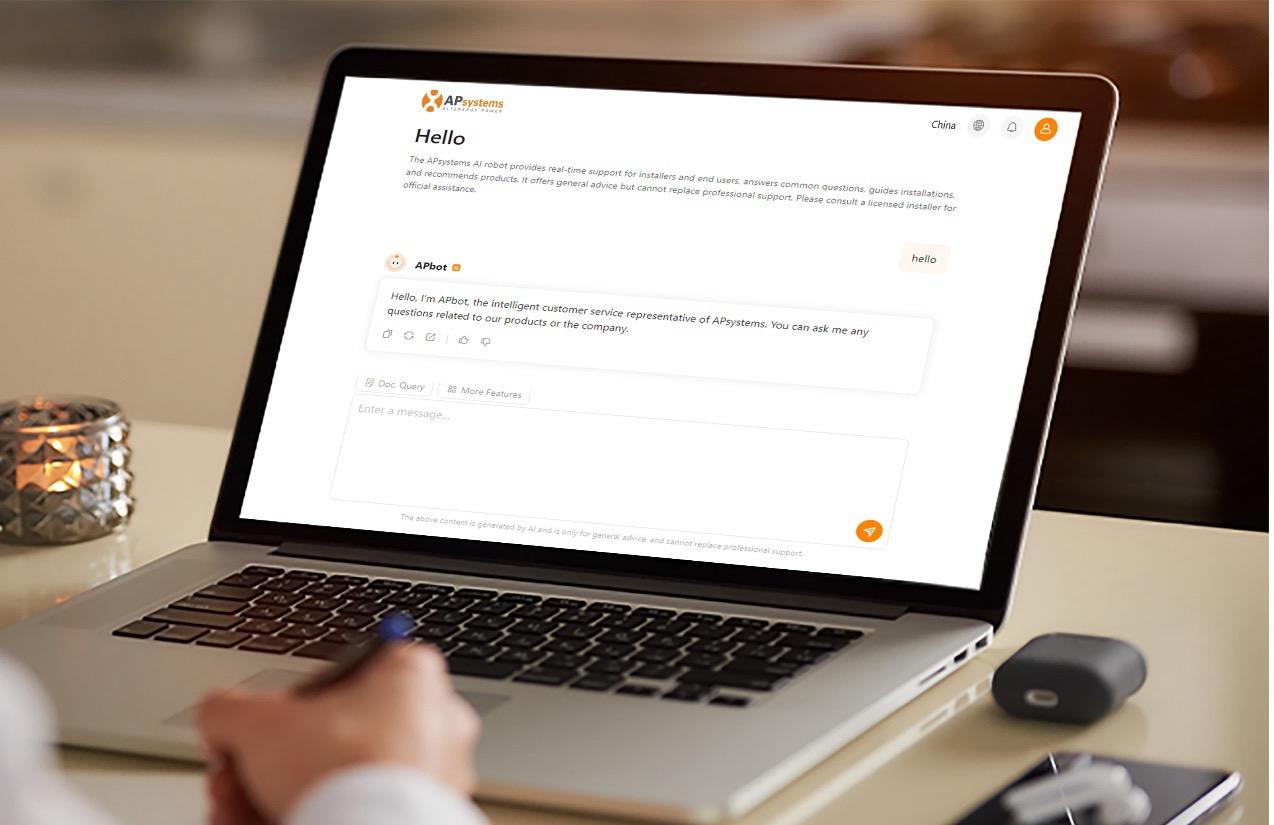

Customer support has also evolved. APbot, APsystems’ AI assistant, uses large language models and retrieval-augmented generation (RAG) to provide fast, accurate answers to customer questions across pre-sales, installation, and post-sales phases.

Built on a comprehensive technical and product knowledge base, APbot supports multiple deployment options—from embedded web chat to integration with the EMA platform and mobile app. It also includes smart features like contextual follow-ups, video recommendations, and multilingual support for global markets—all monitored in real time to ensure quality and compliance.

A Company-Wide AI Strategy

AI isn’t just a product feature—it’s part of APsystems’ company DNA. Through internal programs like the “+AI Application Research Institute” and “AI Open Day,” the company is investing in AI literacy, streamlining workflows, and identifying new ways to bring intelligent automation into daily operations.

By committing to real-world, value-driven AI adoption, APsystems is expanding its “Smart Energy + AI” ecosystem to deliver a more connected, efficient, and sustainable future.